We do the ground work that makes your project more remarkable.

Planning

Loucks started as a planning firm in 1976 when founder Tom Loucks welcomed the City of Independence as his first client. Nearly four decades later, we offer a strategic mix of consulting services while remaining true to our planning roots.

Civil Engineering

When it comes to civil engineering services, our best work is buried. Literally. Once completed, most of our civil engineering efforts are invisible to the naked eye.

Land Surveying

Loucks has performed many of the most complex surveys in the Twin Cities and greater Minnesota.

Landscape Architecture

Loucks’ landscape architecture team consists of a wide variety of talented design professionals with a diverse portfolio that includes master planning, land use, parks and trails, landscape design, streetscapes and cemetery planning.

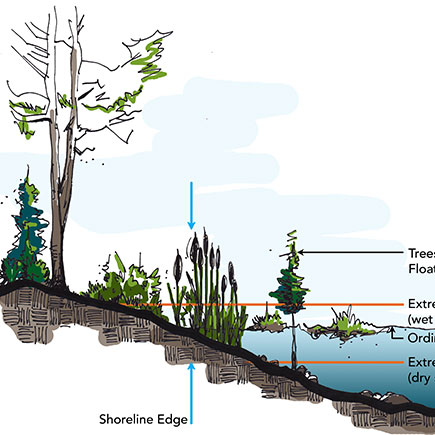

Environmental

Loucks has nearly 40 years of experience working with regulatory agencies. We understand the requirements and intricacies involved in environmental permitting and the agency approval process. Loucks inspires clients to make the best use of their land by providing environmentally sound design.